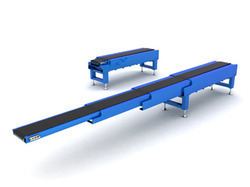

Inclined conveyor systems are essential tools in many industries, helping move materials efficiently between different elevation levels. In Mumbai, where space is at a premium, these systems play a crucial role in optimizing space, increasing productivity, and improving overall operational efficiency. They are widely used in various industries, from manufacturing and logistics to food processing and construction, offering a versatile solution for material handling needs.

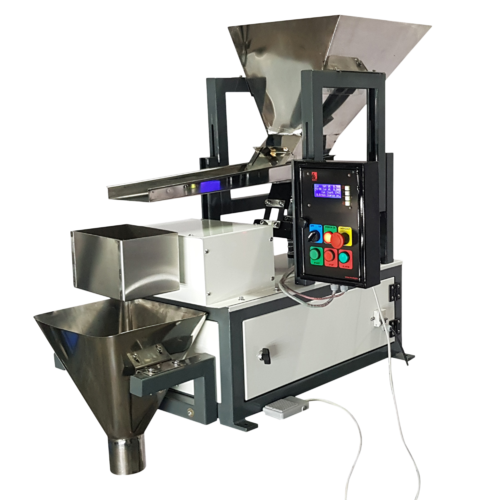

If you want to incline a bulky material to match a production line or to give support to your employees, then Perfection Engineering Corporation is here for you with their best-inclined conveyors systems to offer you the necessary flexibility. The inclined conveyor systems we provide, come with equipped infeed, outfeed, and horizontal sections to provide better product handling control. Our inclined conveyor systems are perfect for doing product transferring as per the needs of the buyers.

The inclined conveyor systems are available with different types of belts such as standard flat belts, modular plastic belts, cleated plastic belts, making them a highly versatile material handling tool. We also offer you the opportunity to create a custom inclined conveyor systems according to your needs.

Design and Components of Inclined Conveyor Systems

Inclined conveyor systems are designed to transport materials at angles, typically between 10 to 30 degrees, depending on the type of materials being moved. Their key components include:

- 1. Belt Profile: The conveyor belt is usually made from materials such as PVC, rubber, or fabric. The belt is designed to provide traction and prevent slippage, which is particularly important when transporting materials at an incline. The choice of belt material depends on the application, including the type of goods, weight, and the operational environment.

- 2. Frame and Structure: The conveyor's frame, typically constructed from robust materials like steel or aluminum, provides the necessary support and stability to handle the stress associated with inclined transportation. The structure must be durable enough to endure constant use and the weight of the materials being transported.

- 3. Drive System: The drive system includes motors and gearboxes that ensure the smooth and consistent movement of the belt. Variable speed controls are often integrated into the system to allow operators to adjust the speed based on specific operational requirements.

- 4. Support Rollers and Pulleys: These components are essential for keeping the belt aligned and facilitating smooth operation. Inclined conveyors use additional support rollers to handle the extra tension and force exerted by the load on an incline.

- 5. Side Guides and Cleats: To prevent materials from sliding off the belt during incline transport, side guides are often added. For steeper inclines, cleats or ridges may be attached to the belt to provide additional grip and prevent materials from sliding backward.

Advanced Technology and Features of Inclined conveyor systems

Modern inclined conveyor systems are increasingly equipped with advanced technologies that enhance their functionality, efficiency, and ease of use. Some of the technological advancements include:

- 1. Automation and Control Systems: Advanced control systems, such as Programmable Logic Controllers (PLC) and Human-Machine Interfaces (HMI), are often integrated into inclined conveyors. These systems allow operators to control the speed, direction, and other operational parameters in real-time, optimizing performance based on specific needs.

- 2. Energy-Efficient Motors: Many inclined conveyor systems are equipped with energy-efficient motors and variable speed drives to reduce power consumption and lower operational costs. This is particularly important for companies in Mumbai looking to meet sustainability goals and reduce their environmental footprint.

- 3. IoT Integration: With the integration of the Internet of Things (IoT) technology, conveyor systems can now be monitored remotely in real-time. Sensors provide data on system performance, enabling predictive maintenance and reducing downtime caused by mechanical failures.

Why choose our Inclined conveyor systems in Mumbai

Here are compelling reasons why customers might like to choose your Inclined Conveyor Systems in Mumbai:

We also serve Inclined conveyor systems in multiple cities like in Kolkata, Pune, Gurgaon