In the bustling industrial landscape of Ahmedabad, the demand for efficient material handling solutions has led to the widespread use of

industrial conveyors. These systems are vital for streamlining operations across various sectors, including manufacturing, logistics, food processing, and pharmaceuticals. This guide aims to provide a detailed overview of industrial conveyors in Ahmedabad, covering their types, applications, manufacturers, and benefits.

What are Industrial Conveyors?

Industrial conveyors are mechanical devices designed to transport materials from one location to another within a facility. They can handle a wide variety of goods, from bulk materials to packaged products. The primary function of conveyors is to facilitate the movement of materials efficiently, reducing manual labor and increasing productivity.

Types of Industrial Conveyors

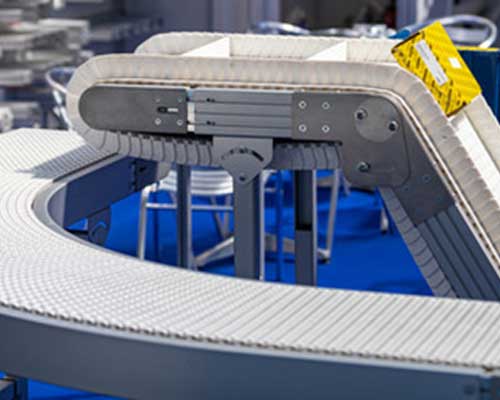

There are several types of industrial conveyors commonly used in Ahmedabad, each serving specific functions:

- Belt Conveyors: The most widely used type, suitable for transporting bulk materials and packaged goods.

- Roller Conveyors: Ideal for handling heavier items, often used in warehousing and distribution centers.

- Chain Conveyors: Suitable for moving heavy or large items, commonly found in automotive and manufacturing industries.

- Screw Conveyors: Used for moving granular materials in a controlled manner.

- Bucket Elevators: Designed for vertically lifting bulk materials, often used in agriculture and food processing.

Applications of Industrial Conveyors

Industrial conveyors are versatile systems used across various industries in Ahmedabad:

- Manufacturing: Used for transporting raw materials and finished products within factories.

- Food Processing: Ensures efficient movement of ingredients and packaged food items.

- Pharmaceuticals: Facilitates the handling of raw materials and finished pharmaceutical products in a hygienic manner.

- Logistics and Warehousing: Essential for sorting and distributing packages in warehouses.

- Mining: Used for transporting mined materials from extraction points to processing facilities.

Benefits of Industrial Conveyors

The integration of industrial conveyors into production lines and material handling processes offers numerous advantages:

- Increased Efficiency: Automating the movement of materials reduces the time taken for transport, enhancing overall productivity.

- Reduced Labor Costs: Minimizes the need for manual handling, leading to lower labor costs and reduced risk of workplace injuries.

- Improved Safety: Conveyors can handle heavy and hazardous materials, reducing the risk of accidents associated with manual lifting.

- Versatility: Suitable for a wide range of materials and applications, making them adaptable to various industries.

- Consistency: Provides a consistent flow of materials, ensuring that production schedules are maintained without interruption.

Factors to Consider When Choosing Industrial Conveyors

Selecting the right industrial conveyor system involves several considerations:

- Material Type: Consider the characteristics of the materials being transported, such as weight, size, and fragility.

- Space Availability: Assess the layout of your facility to determine the most suitable conveyor design.

- Speed and Capacity: Ensure that the conveyor can meet the speed and capacity requirements of your operations.

- Maintenance: Choose a conveyor system that is easy to maintain to minimize downtime and repair costs.

- Compliance: Ensure that the selected conveyor meets industry standards and regulations, especially in food and pharmaceutical sectors.

Future Trends in Conveyor Technology

The conveyor industry is continually evolving, with new technologies enhancing efficiency and performance. Some emerging trends include:

- Smart Conveyors: Integration of IoT technology for real-time monitoring and data analytics to optimize operations.

- Automation: Increasing automation in conveyor systems to improve productivity and reduce human intervention.

- Energy Efficiency: Development of eco-friendly conveyor solutions that consume less energy.

- Modular Design: More flexible conveyor systems that can be easily adjusted or expanded based on operational needs.

Perfection Engineering Corporation is present here to fulfill your requirements, without forcing you to compromise. We have the most experienced professionals for manufacturing and supplying the best Industrial Conveyors in multiple cities like in Pune, Gujarat, Kanpur and in mnay more according to the needs of our valued customers. The use of industrial conveyor system in Ahmedabad that we manufacture vary with the kind of product that you will move with the help of conveyor.