Ahmedabad, a significant industrial hub in India, is home to various manufacturing and processing industries. The city’s robust industrial ecosystem requires efficient and reliable material handling solutions. One such solution is the

inclined belt conveyor, which is designed for the smooth transportation of materials between different levels of production processes. In this article, we will explore the details of inclined belt conveyors, their applications, benefits, and key manufacturers in Ahmedabad.

What is an Inclined Belt Conveyor?

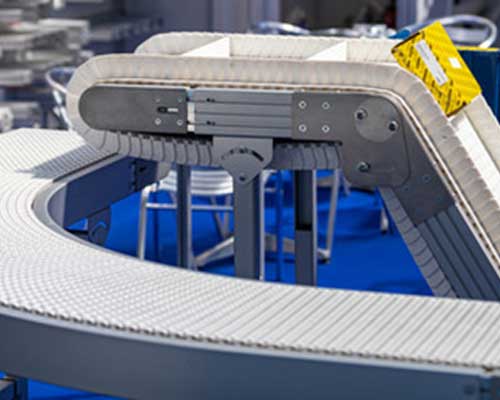

An inclined belt conveyor is a type of conveyor system used to move materials from one level to another, usually at an upward or downward angle. Unlike horizontal belt conveyors, which transport materials on a flat surface, inclined belt conveyors are equipped to overcome elevation changes, making them ideal for factories with multi-level production or warehouse settings. The belt is usually equipped with cleats or rough surfaces to ensure material does not slip during transportation.

Applications of Inclined Belt Conveyors in Ahmedabad

Inclined belt conveyors are utilized in a variety of industries in Ahmedabad, contributing to increased productivity and smooth material flow. Some of the key industries that benefit from this conveyor type include:

- Food Processing: In the food industry, inclined conveyors help in moving raw materials, ingredients, and packaged goods between different levels of production lines.

- Pharmaceutical Industry: In pharmaceutical plants, these conveyors are used to transport medicinal products and raw materials across different stages of production.

- Textile Industry: Inclined conveyors aid in moving fabric, yarn, and other raw materials across different stages of production.

- Packaging Industry: For transporting packaged goods from one level to another, these conveyors are highly efficient.

- Automobile Industry: Parts and components in the automobile industry are often transported using inclined conveyors during assembly and production.

Benefits of Inclined Belt Conveyors

Inclined belt conveyors offer a range of benefits, particularly for industries that require the movement of materials across different levels. Some of the most notable advantages include:

- Space Efficiency: By transporting materials vertically or at an incline, these conveyors make the most of available floor space in a facility.

- Improved Workflow: Inclined conveyors streamline the transportation process by reducing manual handling and labor costs.

- Energy Efficiency: Many modern inclined belt conveyors come equipped with energy-efficient motors, leading to lower power consumption.

- Reduced Material Spillage: The use of cleats or rough-surfaced belts prevents materials from slipping during transport, reducing waste and ensuring smooth operation.

- Customization: These conveyors can be customized in terms of belt width, angle of inclination, and length to suit specific industrial requirements.

Key Features of Inclined Belt Conveyors

Inclined belt conveyors come with several key features that make them highly effective in industrial operations. These include:

- Adjustable Angles: Inclined conveyors can be designed to operate at different angles, depending on the material and the facility’s requirements.

- Cleated Belts: Cleats on the belts help to hold materials in place while the conveyor is in motion, reducing spillage and ensuring efficiency.

- Durable Construction: Made from high-quality materials like stainless steel, these conveyors are durable and can withstand harsh industrial environments.

- Low Maintenance: Inclined belt conveyors are easy to maintain and have a long operational life, thanks to their sturdy design and high-quality components.

- Safety Features: Many conveyors are equipped with safety guards, emergency stop buttons, and sensors to ensure safe operation.

Choosing the Right Inclined Belt Conveyor

When selecting an inclined belt conveyor for your operations, several factors should be considered to ensure that you get the most efficient and suitable system for your needs:

- Material Type: Understanding the type of material you intend to transport will help determine the best belt type and cleat design.

- Conveyor Angle: Depending on the angle of inclination required for your facility, different belt designs may be necessary.

- Load Capacity: It’s important to choose a conveyor that can handle the weight of the materials being transported without compromising performance.

- Environmental Considerations: If your operation takes place in a harsh environment, such as extreme temperatures or high levels of moisture, choosing a conveyor made of suitable materials is crucial.

- Customizability: Ensure the conveyor can be customized in terms of size, shape, and other specifications to meet the exact requirements of your facility.

Perfection Engineering Corporation provides the best-inclined belt conveyors in the regions like Ghaziabad, Faridabad, Gurgaon, and in many more...