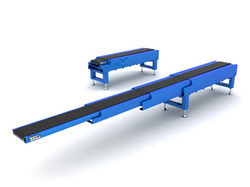

What is the purpose of Perfection Engineering Corporations Infeed Conveyor System?

Perfection Engineering Corporations Infeed Conveyor System is designed to streamline the process of feeding raw materials or products into various manufacturing or processing lines. It ensures a consistent and efficient flow of materials reducing manual labor and enhancing production efficiency.