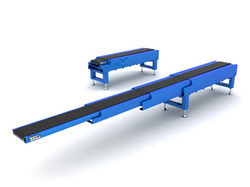

We manufacture our qualitative range of Modular Belt Conveyors by using the latest technology; these conveyors are fabricated with powder coating to make sure that it becomes corrosion resistance and durable. Our products are further tested on the international quality parameter to ensure that they have no defect left in them.

What is a Modular Belt Conveyor?

A modular belt conveyor is a type of conveyor system that utilizes a belt made up of interlocking, plastic segments or modules. These modular belts are designed to be easily replaceable and customizable for specific industries. Unlike traditional flat or rubber belt conveyors, modular belt conveyors are more durable, easier to maintain, and offer flexibility in the design for various applications.

Modular belt conveyors are known for their ability to transport goods around curves and inclines, making them particularly useful in industries where space is limited or materials need to be moved through complex paths. The open design of the belts allows for easy cleaning, making them ideal for food processing, beverage production, and other applications that require high hygiene standards.

Types of Modular Belt Conveyors

There are several types of modular belt conveyors that can be customized based on specific operational needs. The most common types include:

- 1. Straight Modular Belt Conveyors: These conveyors are designed to transport materials in a straight line. They are ideal for transporting products over short or long distances without any elevation or directional changes.

- 2. Inclined Modular Belt Conveyors: These conveyors are designed to move products at an incline or decline. They are used in industries that require materials to be transported between different floor levels or elevated sections of a production line.

- 3. Curved Modular Belt Conveyors: These conveyors allow materials to be transported around corners or along curved paths, helping to maximize space in a facility. They are ideal for industries with limited floor space or for complex production line layouts.

- 4. Swivel or Pivot Modular Conveyors: These conveyors can pivot or change direction as needed, making them perfect for dynamic production environments that require flexibility in material handling.

Key Benefits of Modular Belt Conveyors

Modular belt conveyors offer several key benefits that make them an ideal choice for industrial applications in Faridabad. Some of the primary advantages include:

- 1. Durability and Longevity: The plastic modular belts are highly durable and resistant to wear and tear, making them suitable for harsh environments. They can handle heavy loads and last longer than traditional conveyor belts.

- 2. Easy Maintenance: One of the major benefits of modular belt conveyors is their modular nature, which allows individual belt segments to be easily replaced. This reduces downtime and maintenance costs compared to replacing entire belts.

- 3. Flexibility: Modular belt conveyors are highly customizable and can be designed to handle different shapes, sizes, and types of products. They can be configured to accommodate curved paths, inclines, or declines.

- 4. Hygienic Design: Many modular belt conveyors are made with food-grade plastic, which is easy to clean and resistant to moisture. This makes them ideal for food and beverage production, where hygiene is critical.

- 5. Energy Efficient: Modular belt conveyors typically require less energy to operate than traditional conveyor systems, thanks to their lightweight and low-friction design. This results in lower operational costs over time.

- 6. Adaptability: The modular nature allows the conveyor to be reconfigured or extended as needed. This makes it ideal for industries with evolving production lines or changing needs.

Applications of Modular Belt Conveyors in Faridabad

Modular belt conveyors are used in a wide range of industries in Faridabad, providing an efficient and versatile solution for material handling needs. Some of the key applications include:

- a. Food Processing: Modular belt conveyors are extensively used in food processing plants due to their hygienic design. They are ideal for transporting food products, such as fruits, vegetables, meat, and bakery goods, through different stages of production.

- b. Beverage Industry: In beverage manufacturing, modular belt conveyors are used to transport bottles, cans, and containers through filling, capping, and packaging stations.

- c. Pharmaceuticals: The modular belts are also used in the pharmaceutical industry to transport medicines, capsules, and medical products through different processing stages while maintaining cleanliness and sterility.

- d. Automotive Industry: Modular belt conveyors are used in assembly lines to transport parts, components, and finished products in the automotive sector. Their flexibility allows them to handle different sizes and weights of materials.

- e. Packaging: Modular belt conveyors are ideal for transporting packaging materials, including boxes, cartons, and containers, through sorting and packaging stations. They are often used in conjunction with automated systems for efficient packaging.

- f. Logistics and Warehousing: Modular belt conveyors are commonly used in distribution centers and warehouses to transport goods between different areas, such as loading docks, sorting areas, and storage zones.

Why Modular Belt Conveyors Are Ideal for Industries in Faridabad

Faridabad is a bustling industrial region with a wide range of industries, including manufacturing, food processing, automotive, and pharmaceuticals. Modular belt conveyors are an excellent choice for industries in Faridabad due to their adaptability, durability, and ability to handle various materials efficiently. The modular design allows businesses to adjust and reconfigure the conveyors based on their changing production needs.

With industries in Faridabad constantly seeking efficient material handling solutions to stay competitive, modular belt conveyors offer the versatility required for different production environments. The ease of maintenance and repair also means that industries can minimize downtime, keeping production lines running smoothly.

Customization Options for Modular Belt Conveyors

Modular belt conveyors can be customized to fit the specific needs of a business. Common customization options include:

- a. Belt Material: The modular belt can be made from various materials, such as food-grade plastic for food processing or durable polymers for heavy-duty industrial use.

- b. Conveyor Size: The length, width, and height of the conveyor can be adjusted to accommodate different product sizes and production lines.

- c. Speed Control: Variable speed drives can be incorporated to control the conveyor’s speed based on production requirements.

- d. Incline/Decline Angles: Modular belt conveyors can be designed to operate at various incline or decline angles to transport products between different elevations.

We offer Modular Belt Conveyors in mutiple cities like in Pune, Mumbai, Surat, and in many more...