Faridabad, a bustling industrial city in northern India, is home to a variety of manufacturing and logistics operations. One of the essential components that facilitate the efficient movement of materials in these operations is the inclined belt conveyor. This article explores the features, applications, advantages, and benefits of choosing inclined belt conveyors from Perfection Engineering Corporation in Faridabad.

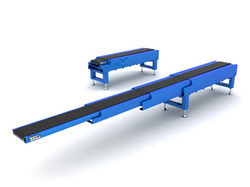

The inclined belt conveyors that we manufacture, known as inclined belt conveyor in faridabad, are largely used to transfer loads on different floors or levels of the buildings. We have designed these conveyors in such a way that only a small floor space is required to install them. For high grip, these conveyors take help of structured and smooth-surfaced top belts.

What is an Inclined Belt Conveyor?

An inclined belt conveyor is a type of conveyor system designed to transport materials at an upward or downward angle. The belt is typically made of durable materials like rubber or PVC, allowing it to handle various loads, from lightweight items to heavier products. Inclined belt conveyors are commonly used in manufacturing, warehousing, and distribution facilities to optimize vertical space and enhance operational efficiency.

How Inclined Belt Conveyors Work

The operation of inclined belt conveyors is straightforward. The belt moves over rollers and pulleys, allowing materials to be transported along the conveyor. As the belt moves, items placed on it are carried up or down to the desired elevation. The angle of inclination can be adjusted based on the specific requirements of the application, enabling seamless integration into existing production lines or storage facilities.

Types of Inclined Belt Conveyors

Inclined belt conveyors come in various designs to accommodate different industrial needs. Some common types include:

- a. Standard Inclined Belt Conveyors: These conveyors feature a simple belt design and are suitable for transporting lightweight to medium-weight products over short distances.

- b. Cleated Belt Conveyors: Equipped with raised sections (cleats) on the belt, these conveyors prevent items from slipping backward during transportation, making them ideal for bulk materials and loose items.

- c. Modular Belt Conveyors: Composed of interlocking plastic segments, these conveyors can be customized for various applications, offering flexibility in design and functionality.

- d. Inclined Belt Conveyors with Side Guards: Inclined Belt Conveyors Systems feature raised side edges to prevent materials from falling off during transport, making them suitable for transporting fragile or loose items.

Applications of Inclined Belt Conveyors in Faridabad

Inclined belt conveyors are widely utilized across various industries in Faridabad. Some key applications include:

- a. Manufacturing: In manufacturing plants, inclined belt conveyors facilitate the movement of raw materials and finished goods between different production stages, enhancing efficiency.

- b. Food Processing: The food industry uses inclined belt conveyors for transporting products through different processing stages, ensuring hygiene and compliance with industry standards.

- c. Pharmaceuticals: In pharmaceutical manufacturing, inclined conveyors help move delicate materials while maintaining strict hygiene and safety standards.

- d. Packaging: These conveyors are commonly used in packaging lines to transport products from one station to another, streamlining the packaging process.

- e. Logistics and Warehousing: Inclined belt conveyors are essential in warehouses for moving goods to higher storage levels or loading docks, optimizing space and improving accessibility.

Benefits of Inclined Belt Conveyors

Inclined belt conveyors offer several advantages that make them a preferred choice for many industries in Faridabad:

- a. Space Optimization: By utilizing vertical space effectively, inclined belt conveyors help companies maximize their operational area, particularly in facilities with limited floor space.

- b. Increased Efficiency: These conveyors streamline the movement of goods, reducing manual handling and increasing overall productivity in operations.

- c. Cost-Effective: Automating the transport of materials minimizes labor costs associated with manual loading and unloading, making inclined belt conveyors a cost-effective solution.

- d. Enhanced Safety: Inclined conveyors reduce the risk of injuries related to manual lifting, providing a safer working environment for employees.

- e. Customizability: Inclined belt conveyors can be tailored to meet specific needs, including adjustments to belt material, incline angle, and load capacity.

Challenges of Inclined Belt Conveyors

Despite their many benefits, inclined belt conveyors may also present some challenges:

- a. Initial Investment: The upfront cost of purchasing and installing inclined belt conveyors can be significant, particularly for large systems.

- b. Maintenance Requirements: Regular maintenance is essential to keep the system running smoothly. This includes checking the belt for wear, ensuring proper tension, and lubricating components.

- c. Space Constraints: While inclined conveyors save horizontal space, they may require adequate vertical clearance to function effectively, which can be a limitation in some facilities.

- d. Load Limitations: Each inclined conveyor has a specific load capacity, and exceeding this limit can lead to equipment failure or safety hazards.

Customization Options for Inclined Belt Conveyors

Inclined belt conveyors can be tailored to meet the specific needs of businesses. Some common customization options include:

- 1. Belt Material: The type of belt material can be customized based on the materials being transported, including options for food-grade belts in food processing applications.

- 2. Incline Angle: The angle of incline can be adjusted to accommodate different elevation requirements, ensuring optimal material flow.

- 3. Load Capacity: Conveyors can be designed to handle varying load capacities, from lightweight packages to heavy industrial components.

- 4. Automation Features: Advanced features such as sensors and programmable controls can be integrated into the conveyor system for improved automation and efficiency.

Our inclined belt conveyors are able to carry heavy materials, and the best thing about these conveyors is that their belts can withstand harsh environments easily. They are used to discharge load at a selected location that is chosen by the user. The conveyor can get set at any angle to convey material from floor-to-floor or building to truck.

We also provide Inclined Belt Conveyors in multiple cities like in Delhi, Kolkata, Mumbai, and in many more...